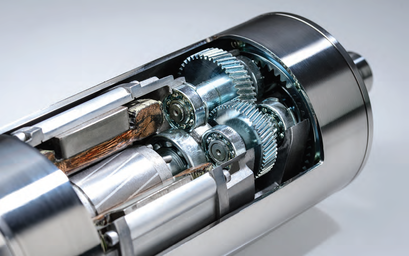

Cranberry manufacturing benefits from more reliable, longer lasting and more sanitary drive technology Who is Rulmeca? What is a Rulmeca Motorized Pulley? A Rulmeca Motorized Pulley is the ideal system for the drive of belt conveyors. Being composed of a motor, bearings and gearbox hermetically enclosed inside the casing, it is partially filled with oil that acts as lubricant and refrigerant to dissipate away the heat through the shell and the belt conveyor. The main features of our Motorized Pulleys, all made by Rulmeca, are:

This is how we help. This is an example of where Rulmeca provided all of the above improvements for a cranberry manufacturer. The cranberry manufacturer was using exposed drives consisting of a right angle gearbox and motors, sometimes involving a coupled connection or chain and sprockets to the drive shaft. These drives often times had drip trays under them to catch leaking oil from the output seals. Rulmeca Motorized Pulleys were installed and

Rulmeca Offers IP69 (food processing) Motorized Pulley shaft seal system With IP69 rating Rulmeca offers complete assurance to food handling customers. Rulmeca has received the certification of an upgraded Ingress Protection rating IP66/69 for drum motors 80LS, 113LS, 138LS and 165LS in stainless steel. The goal of the certification procedure was to achieve official IP69 (acc. to DIN EN 60529) confirmation of the current TS8N (complete stainless steel outer material with VITON dust lip seal and PTFE deflection seal) sealing system. To provide absolute objectivity and safety the test was conducted at the independent VDE test and certification institute. In the test setup the drum motors have been mounted on a supporting structure and sprayed from 4 fixed angles (0°, 30°,60°, 90°) with a flat nozzle, each jet duration lasting at least 30 seconds. Distance between nozzle and test item was 100-150mm at a pressure of 100 bar with a water temperature of 80°C.

6 Comments

1/30/2019 05:46:59 pm

If I had to get a pully, I would want something like this. Seeing that is it motorized is pretty neat and overall safer. Now I'd just be sure to get the right one for the given application that I would use it for.

Reply

6/24/2021 07:44:00 pm

I am looking to learn about pulley motors suitable for production at llc. I wonder if this pulley will be effective when put on the production line. I need some reference, thanks for your post.

Reply

Megan Seiltz

6/25/2021 02:38:06 pm

Hello! Thank you for your comment. Could you reply, or send me an email at [email protected], with your contact information so we can help you further? Thank you!

Reply

8/6/2021 07:56:32 am

I am glad there are refrigerants to help get rid of heat in the conveyor belt. That would save me a ton of maintenance. It would also allow me to let the belt run for longer periods of time.

Reply

Megan Seiltz

8/9/2021 09:20:38 pm

Hello! We have received your comment and are wondering if you can give us more information so we can connect to see how we can help! Could you please reply, or send me an email at [email protected], with your contact information and we can get in touch? Thank you!

Reply

7/29/2023 09:09:43 am

I was captured when you discussed that motorized pulleys can increase safety with fewer pinch points. My friend told me that their facility needs timing belt pulleys. I should advise him to turn to an established US manufacturer of precision transport components.

Reply

Leave a Reply. |

|

OFFICE LOCATIONS

Neenah, WI Milwaukee, WI |